Understanding Garage Floor Coating Longevity in Bakersfield’s Harsh Climate

When you’re investing in a garage floor coating, you want to know one thing: how long will it actually last? It’s a fair question, especially in Bakersfield where summer temperatures regularly soar above 100°F and UV exposure is relentless. The answer isn’t as simple as you might hope, because not all garage floor coatings are created equal.

The lifespan of your garage floor coating depends on three critical factors: the product system used, the quality of surface preparation, and the environmental conditions it faces. In Bakersfield’s challenging climate, these factors become even more important. Let’s break down what you need to know to make an informed decision.

The Reality of DIY Coating Systems

Walk into any big-box home improvement store and you’ll find garage floor coating kits promising professional results for a fraction of the cost. The truth? Most homeowners using these DIY epoxy kits find themselves redoing their floors every 12 months in Bakersfield’s climate.

Most retail kits use water-based or solvent-based epoxies with minimal thickness. They’re designed for easy application by homeowners, which means they sacrifice durability for convenience. The biggest issue? They weren’t engineered to handle extreme temperature fluctuations or the intense UV exposure that Bakersfield garages experience, especially in homes with direct sun exposure.

Here’s what most people don’t consider: the true cost of DIY coatings isn’t just the $200-400 kit price. It’s the annual cycle of emptying your entire garage, spending a weekend on application, waiting for cure time, and moving everything back in—only to repeat the process 12 months later when the coating starts failing. After three years, you’ve spent over $1,000 in materials alone, plus countless hours of labor and the ongoing frustration of a floor that never quite lives up to expectations.

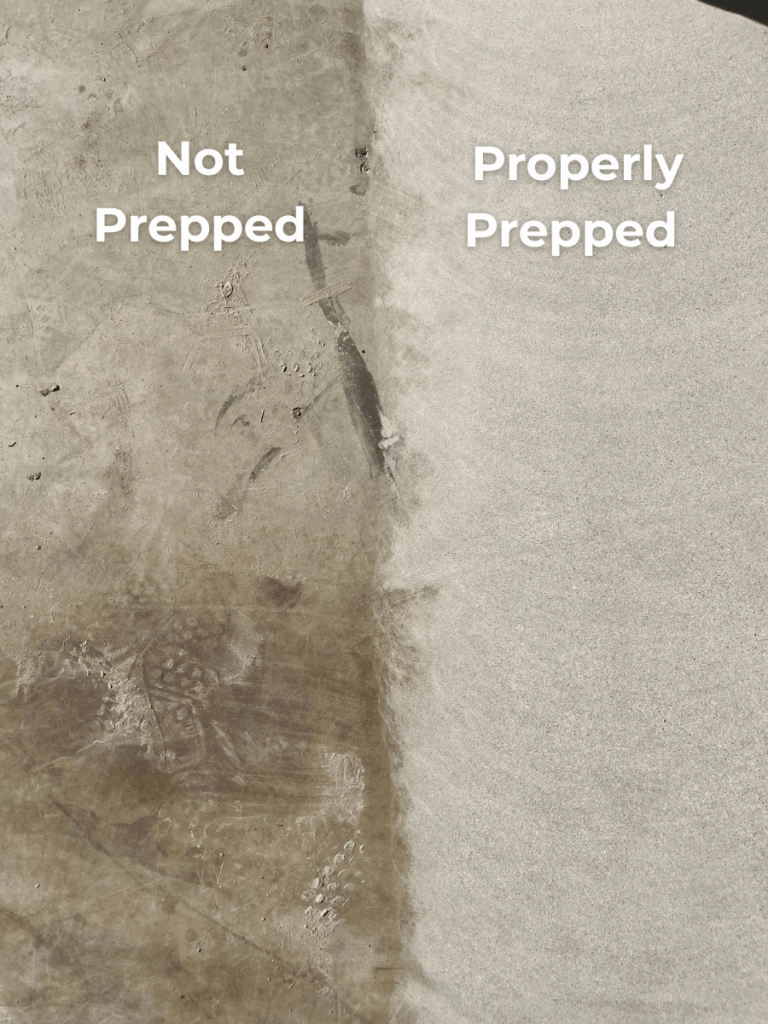

Beyond product limitations, DIY installations almost always fail because of inadequate surface preparation. Most homeowners rent basic floor grinders or use acid etching, neither of which creates the proper surface profile needed for long-term adhesion. Without professional diamond grinding equipment, even the best coating won’t bond properly to your concrete, leading to delamination and premature failure.

Professional Surface Preparation: The Foundation of Everything

Here’s the truth that separates amateur results from professional-grade longevity: proper surface preparation is more important than the coating itself. You could use the world’s most advanced coating system, but without the right surface profile, it will fail.

Professional installation begins with diamond grinding the concrete to achieve a CSP (Concrete Surface Profile) of 2. This specific profile opens up the concrete’s pores at the microscopic level, creating the ideal surface for coating adhesion. It’s not about making the floor look rough—it’s about creating the mechanical bond that allows coatings to become part of the concrete rather than just sitting on top of it.

Diamond grinding also accomplishes what acid etching and rental grinders can’t: it removes all existing sealers, oils, contaminants, and the weak surface layer of concrete known as laitance. This preparation step alone can be the difference between a coating that lasts 1 year and one that lasts 15 or more.

We also address cracks during preparation by properly routing and filling them. However, control joints in garages serve an important purpose—they’re designed to allow the concrete to move naturally. We don’t fill control joints because concrete needs that flexibility, especially in Bakersfield’s expansive soil conditions where seasonal movement is common.

Moisture testing rounds out the preparation process. Concrete must be within acceptable moisture levels before coating application. High moisture levels lead to coating failure, regardless of the product quality. Professional installers use calcium chloride tests or relative humidity probes to verify moisture levels before beginning application.

Professional One-Day Floor Systems: 10-15 Year Performance

Our primary professional coating systems are designed for efficient installation without sacrificing durability. These one-day systems deliver 10-15 years of reliable performance—a dramatic improvement over annual DIY replacements.

The key is using advanced polyurea or polyaspartic basecoats. These aren’t your big-box store epoxies. Polyaspartic coatings cure rapidly while creating an incredibly strong bond with properly prepared concrete. Unlike traditional epoxy, polyaspartic coatings are UV-stable, meaning they won’t yellow or chalk under Bakersfield’s intense sunlight.

The rapid cure time of polyaspartic systems allows for same-day installation and quick return to service—typically within 24 hours. This means minimal disruption to your life. Your garage is emptied, prepared, coated, and ready to use in a single day, rather than the multi-day process required by slower-curing epoxy systems.

These coatings provide excellent chemical resistance, impact resistance, and the flexibility needed to handle Bakersfield’s temperature extremes. During summer, garage floors can experience temperature swings of 50°F or more between night and day. Polyaspartic coatings flex with the concrete as it expands and contracts, preventing the cracking and delamination that plague rigid coating systems.

With proper installation on correctly prepared concrete and reasonable maintenance, our one-day systems consistently deliver on their 10-15 year warranties. For many homeowners, this represents the perfect balance of performance, convenience, and value.

Lifetime Warranty Systems: Built for Decades of Performance

For homeowners seeking the ultimate in durability and longevity, multi-layer systems are engineered to last 20-30 years or more. These aren’t just thicker versions of standard coatings—they’re comprehensive systems where each layer serves a specific purpose.

The Multi-Layer Approach

Lifetime warranty systems begin with an MVB (Moisture Vapor Barrier) primer applied to the properly prepared concrete with a CSP of 2. This critical first layer addresses one of concrete’s biggest challenges: moisture vapor transmission. Concrete is porous and can release moisture vapor from below, which can cause coatings to bubble, delaminate, or fail prematurely. The MVB primer seals the concrete and provides a stable foundation for the layers above.

Next comes a polyurea or polyaspartic basecoat, which provides the primary strength, flexibility, and chemical resistance. This layer is applied at optimal thickness, creating a robust protective barrier that handles the daily demands of garage use.

The third layer is a polyaspartic topcoat, which adds additional UV protection and creates a smooth, easy-to-clean surface. This layer enhances the system’s resistance to staining and makes maintenance simple.

Finally, a urethane topcoat is applied as the ultimate protective layer. Urethane offers exceptional abrasion resistance and provides additional protection against hot tire pickup—a common issue where hot tires from recently driven vehicles can soften certain coatings and pull them up when the car is moved. The urethane topcoat prevents this issue while adding extra gloss and depth to the finish.

This multi-layer approach creates a coating system that’s essentially overbuilt for typical garage use. That’s exactly why it carries a lifetime warranty and why these floors routinely last 20-30 years or more without needing replacement.

What Makes Bakersfield’s Climate So Challenging

Bakersfield isn’t just hot—it’s hot with significant daily temperature swings and intense UV exposure. These conditions stress garage floor coatings in ways that moderate climates don’t.

During summer, garage floor surfaces can exceed 140°F in direct sunlight. When temperatures drop at night, the concrete contracts. This constant expansion and contraction cycle tests the flexibility and adhesion of any coating system. Lower-quality coatings become brittle over time and crack under this stress.

UV exposure is another major factor. Bakersfield receives over 270 sunny days per year. Traditional epoxy coatings weren’t designed for this level of UV exposure and will yellow, fade, or become chalky within months. This isn’t just a cosmetic issue—UV degradation weakens the coating’s molecular structure, reducing its protective capabilities.

The combination of heat and UV also accelerates chemical reactions. Oil, gasoline, and other automotive fluids can etch or stain coatings more quickly in hot conditions. This is why UV-resistant polyaspartic coatings and chemically resistant urethane topcoats are essential for Bakersfield garages.

Choosing Between One-Day and Multi-Layer Systems

Both our professional coating systems offer dramatically longer lifespans than DIY alternatives, but they serve different needs and budgets.

Our one-day polyaspartic systems are ideal for homeowners who want professional-grade durability with minimal disruption and upfront investment. With 10-15 year warranties, these systems eliminate the annual DIY cycle and provide a beautiful, low-maintenance floor that performs year after year. For most homeowners, this is the sweet spot of value and performance.

The multi-layer lifetime warranty system is the choice for homeowners planning to stay in their homes long-term or those who want the absolute best protection available. The per-year cost becomes negligible when you consider 20-30+ years of protection without replacement. You’re also making a significant investment in your home’s value—a professionally coated garage floor with a lifetime warranty is an attractive feature to potential buyers.

The decision often comes down to how long you plan to own your home and how heavily you use your garage. Both systems use the same critical foundation: diamond grinding to CSP 2 and professional-grade polyaspartic coatings. The multi-layer system simply adds extra protection layers for extended longevity.

Maintenance for Maximum Lifespan

Even the most durable coating system benefits from basic maintenance. The good news? Properly installed polyaspartic and urethane systems are remarkably low-maintenance compared to DIY alternatives.

Regular sweeping or dust mopping prevents abrasive dirt particles from dulling the finish over time. For deeper cleaning, a simple mop with warm water and a pH-neutral cleaner is all you need. Avoid harsh chemicals or acidic cleaners that can gradually degrade the coating surface.

Promptly cleaning up automotive fluids prevents staining and chemical etching. While professional-grade coatings resist these substances far better than DIY products, prolonged exposure to aggressive chemicals can still cause damage over time.

Placing mats under vehicles that leak fluids and using floor jacks with rubber pads instead of metal helps prevent point-load damage. These simple precautions can extend your coating’s pristine appearance for years.

The True Cost Comparison

When comparing coating options, looking only at upfront costs tells an incomplete story. The true cost includes replacement frequency, your time, and the ongoing hassle of maintaining a failing floor.

A DIY kit costs $200-400 and requires annual replacement in Bakersfield’s climate. Over 10 years, that’s $2,000-4,000 in materials alone. Add in your labor—conservatively 16 hours per year for preparation, application, and moving items—and you’re looking at 160 hours over a decade. Don’t forget the hassle of emptying your garage annually and the frustration of a floor that never quite looks or performs the way you hoped.

Our professional one-day systems cost more initially but eliminate the replacement cycle for 10-15 years. You invest once, and your garage is done. No annual projects, no repeated expenses, no ongoing frustration. The per-year cost is actually lower than DIY, and you get superior performance throughout the system’s life.

Lifetime warranty systems represent the ultimate value for long-term homeowners. When a coating lasts 20-30+ years, the initial investment becomes remarkably affordable when viewed on a per-year basis. More importantly, you never have to think about your garage floor again.

Making the Right Choice for Your Bakersfield Garage

The lifespan of your garage floor coating comes down to two things: proper surface preparation and professional-grade coating systems. In Bakersfield’s demanding climate, both are non-negotiable for long-term performance.

Diamond grinding to achieve CSP 2 creates the foundation for proper adhesion. Advanced polyaspartic and polyurea coatings provide UV stability, flexibility, and chemical resistance that DIY products simply can’t match. Whether you choose a one-day system with 10-15 year warranty or a multi-layer lifetime warranty system, you’re investing in professional results that eliminate the annual DIY cycle.

Your garage floor is a significant investment in your home’s functionality and appearance. Choosing a coating system designed for Bakersfield’s climate, professionally installed with proper preparation, and backed by a solid warranty ensures you’ll enjoy a beautiful, durable floor for years or decades to come.

Ready to invest in a garage floor coating that’s built to last? Contact us today for a free consultation and quote. We’ll assess your specific needs, explain your options, and help you choose the system that best fits your goals and budget. Whether you’re looking for our efficient one-day system or ultimate lifetime protection, we’ll create a garage floor you’ll still be proud of years from now.