Balancing Durability with Easy Maintenance: A Custom Flooring Solution

When a Bakersfield-area manufacturing facility approached Husky Coatings with a specific vision for their production floor, they had a clear priority: they needed flooring that could withstand the demands of industrial operations while remaining simple to keep clean. Their solution? A sophisticated light blue epoxy system designed for both functionality and aesthetics. This project showcases how thoughtful specification and expert application can deliver a floor that performs as well as it looks.

The client’s facility required four production and support rooms to be refinished. Their challenge wasn’t just about selecting a coating—it was about engineering a system that would handle regular washdowns with a hose, resist moisture infiltration, and maintain a smooth, professional appearance. Through strategic material selection and careful execution, we created a seamless flooring system that exceeded their expectations.

Understanding the Project Requirements: Why Standard Approaches Fell Short

Most manufacturing environments opt for textured epoxy floors with aggressive anti-slip properties. The downside? Texture traps dirt, bacteria, and cleaning solutions, making maintenance labor-intensive and costly. This client wanted something different. They specifically requested a smooth finish that would be easy to sanitize and maintain without compromising safety or durability.

This meant we needed to think strategically about how to achieve slip resistance without relying on traditional broadcasting methods. The solution required a multi-layer system that could deliver both performance and cleanability—something that required precision planning from substrate preparation through final seal.

The Multi-Layer System: Building Protection from the Ground Up

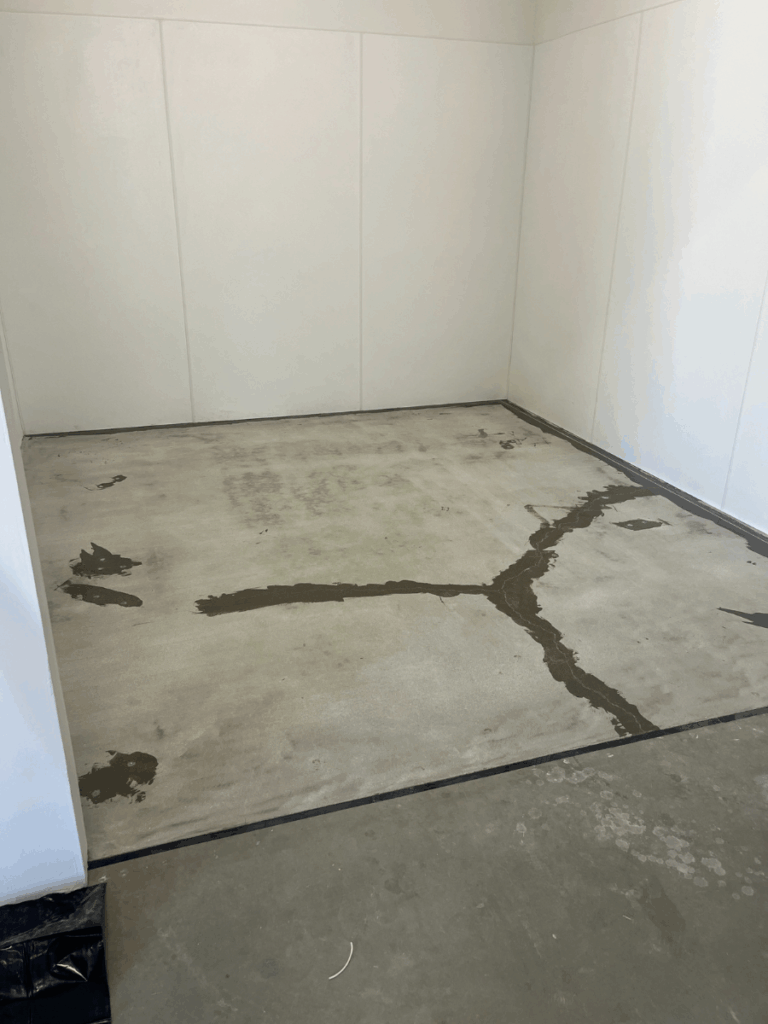

Substrate Preparation: The Foundation of Success

Every quality epoxy installation begins with proper surface preparation. We started with a thorough MVB (moisture vapor barrier) application. In manufacturing environments where washdowns are routine, moisture is a constant threat. The MVB protects the concrete substrate from water infiltration that could compromise the epoxy bond or cause delamination over time.

This critical first step is often overlooked, but it’s what separates floors that last five years from floors that perform for fifteen.

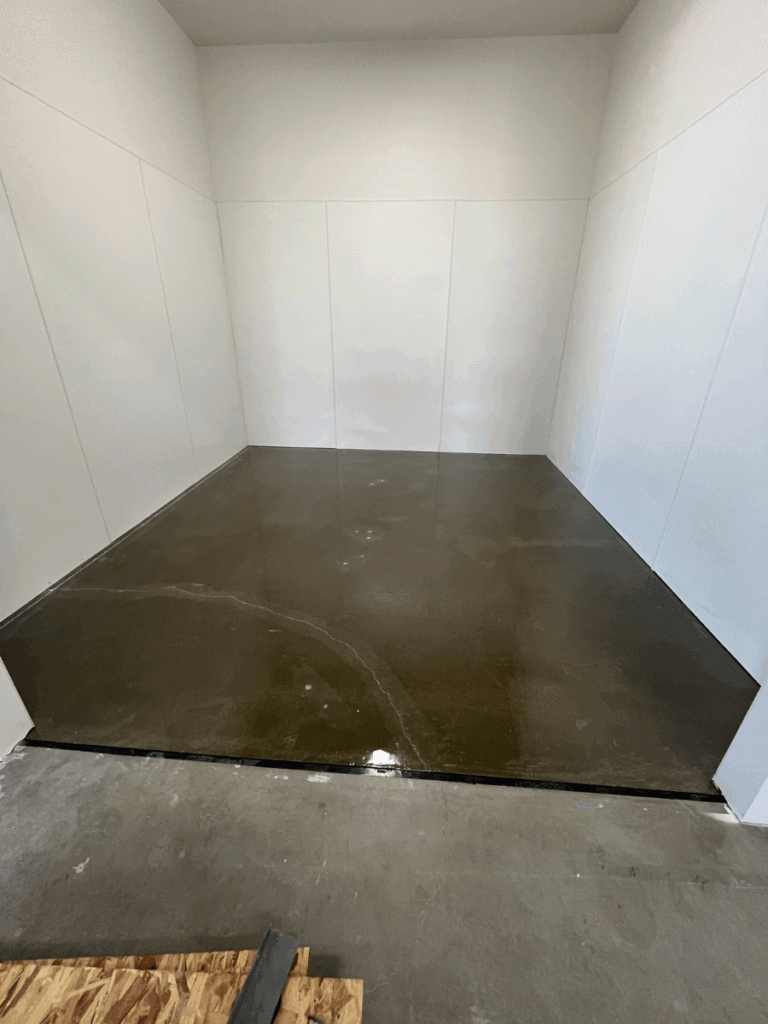

The Epoxy Layer: Creating the Sealed Base

Once the MVB was cured, we applied a robust epoxy coating system. Epoxy serves as the primary workhorse in this application—it provides excellent chemical resistance, abrasion resistance, and bonding properties. For this project, we selected a system specifically formulated to accept urethane topcoats while maintaining the smooth finish the client wanted.

The smooth epoxy layer also means cleaning crews can use pressure washers and hose-downs without worrying about water pooling in textured areas or moisture being trapped beneath the surface.

Urethane Topcoat with Aluminum Oxide: The Safety and Cleanability Balance

Here’s where the project got particularly thoughtful. Rather than broadcasting standard anti-slip aggregate into an epoxy, we applied a urethane topcoat infused with aluminum oxide. This approach offers several advantages:

The aluminum oxide particles are uniformly distributed throughout the urethane rather than sitting loosely on the surface, which means they won’t accumulate dirt in crevices or wash away. The urethane topcoat itself is extremely durable and maintains that smooth, easy-to-clean surface the client prioritized. The slip resistance provides genuine traction for workers even in wet conditions, addressing the safety requirement without sacrificing cleanability.

This hybrid approach gave the facility a floor that’s genuinely slip-resistant while remaining low-maintenance—the best of both worlds.

Finishing Touches: Coving and Sealing for Total Water Protection

The floor system didn’t end at the walls. To create a truly waterproof installation capable of withstanding regular hose-downs, we installed epoxy coving at all base areas. Rather than leaving a vulnerable 90-degree corner where the floor meets the wall, we created a smooth, curved transition.

To complete the waterproof system, we fabricated epoxy coving off-site on wooden substrates, then installed them on-site and sealed all transitions with silicone. This approach ensures perfectly formed curves without the challenges of field-molding coving directly onto the floor. Silicone’s flexibility and water-resistance properties create a complete moisture barrier that accommodates minor movement and thermal expansion. The result is a seamless, waterproof seal that prevents water from migrating behind the coving or compromising the structural integrity of the substrate.

The Results: Performance Meets Aesthetics

Four production rooms now feature a consistent, professional light blue epoxy floor system capable of withstanding daily washdowns without deterioration. The smooth surface reduces cleaning time and labor costs, while the aluminum oxide-infused urethane provides reliable slip resistance. The facility can now maintain rigorous sanitation standards without worrying about the coating system failing or becoming damaged.

Beyond performance, the aesthetic result matters too. The light blue finish creates a clean, modern appearance that boosts the professional atmosphere of the space while improving worker morale and visibility in the facility.

Key Takeaways for Manufacturing Facilities

If you operate a manufacturing environment considering new flooring, this project demonstrates several important principles. First, resist the urge to simply apply a standard textured epoxy—evaluate your actual maintenance needs and performance requirements. Second, understand that smooth doesn’t mean unsafe if you use the right materials and application techniques. Third, don’t overlook critical details like moisture barriers, coving, and perimeter sealing—these elements are what separate adequate floors from exceptional ones.

The difference between a floor that merely tolerates washdowns and one that genuinely thrives under them comes down to thoughtful system design and expert execution.

Ready to Transform Your Facility’s Flooring?

Whether you’re managing a manufacturing operation, warehouse, or industrial facility in Bakersfield or the surrounding area, your flooring choices directly impact safety, maintenance costs, and facility aesthetics. If you’re considering an epoxy flooring system or want to discuss how to solve specific challenges like moisture control or cleanability, Husky Coatings is here to help.

Contact Husky Coatings today to discuss your flooring project and learn how a custom coating system can enhance your facility’s performance and appearance.