Transforming a 3,500 Square Foot Food Processing Facility

This Bakersfield food processing facility needed flooring that could handle freezing temperatures, heavy equipment, and strict sanitary requirements. Our team delivered a complete epoxy floor system designed for extreme conditions and daily use.

Project Overview

Our team recently completed this challenging commercial installation, transforming 3,500 square feet of concrete into a seamless, sanitary surface. The facility included two large freezer rooms, with the main freezer spanning 1,500 square feet.

Project Details:

- Location: Bakersfield, California

- Total Area: 3,500 square feet

- System: MVB primer, epoxy build coat, urethane topcoat

- Special Requirements: Freezer-rated, food-safe, slip-resistant

- Joint Treatment: Polyurea joint filler

- Color: Medium grey with aluminum oxide texture

The Challenge

Food processing facilities face unique flooring demands. This project required thermal cycling resistance (freezer to room temperature daily), chemical resistance against industrial cleaners, slip-resistant surfaces for worker safety, and a seamless finish meeting food safety regulations.

Our Installation Process

Surface Preparation

We started with mechanical surface preparation using industrial diamond grinders. Proper concrete preparation ensures maximum adhesion and long-lasting performance.

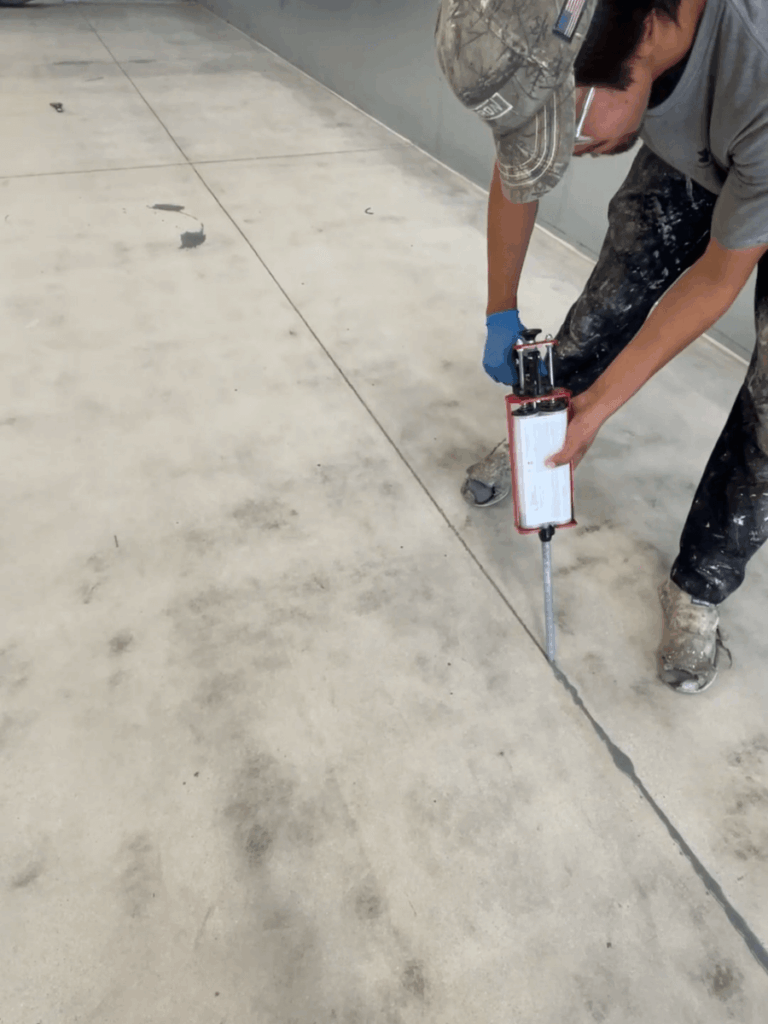

Joint Treatment

Before applying coatings, we filled all concrete joints with flexible polyurea joint filler. This prevents bacteria growth and allows natural concrete movement without cracking.

Three-Layer System

Moisture Vapor Barrier Primer: This clear primer creates an impermeable seal against moisture intrusion from below the concrete.

Epoxy Build Coat: The structural foundation providing impact resistance and durability for heavy equipment traffic, applied in medium grey.

Urethane Topcoat: The performance finish delivers chemical resistance and anti-slip texture through integrated aluminum oxide additives.

Freezer Room Treatment

The freezer areas received special attention with silica sand broadcast into the wet epoxy coating, creating maximum traction in low-temperature environments where safety is critical.

Project Results

The completed installation delivered exactly what this facility needed:

- Seamless, non-porous surface eliminating bacteria-trapping joints

- FDA-compliant finish meeting food safety regulations

- Thermal shock resistance handling daily temperature changes

- Chemical resistance withstanding industrial cleaning products

- Slip-resistant texture ensuring worker safety

- Easy maintenance reducing long-term costs

Why This System Works

This wasn’t just about applying coatings, it was about engineering a solution. The flexible joints allow concrete movement without cracking. The vapor barrier prevents moisture problems. The epoxy provides strength while the urethane delivers chemical resistance and texture needed for daily operations.

Our Commercial Flooring Services

Husky Coatings provides epoxy flooring solutions throughout Bakersfield and Central California. We specialize in restaurants, warehouses, industrial facilities, food processing plants, commercial kitchens, and freezer rooms.

Ready for Your Project?

Transform your commercial space with flooring engineered for your specific needs. Our experienced team delivers durable, high-performance solutions for businesses across all industries.

Contact Husky Coatings today for your consultation. We provide detailed estimates for restaurant flooring, warehouse coatings, office floors, and showroom surfaces throughout the Bakersfield area.

Common Questions

How long does commercial epoxy flooring last? Professional epoxy floors typically provide 10-20 years of service with proper maintenance.

Can epoxy handle freezer temperatures? Yes, our specialized systems are engineered for extreme thermal cycling and sub-zero temperatures.

Is epoxy flooring food-safe? Our coatings meet FDA requirements and provide seamless, sanitary surfaces for food processing.

What does commercial epoxy flooring cost? Costs depend on project size, system complexity, and requirements. Contact us for accurate pricing.

Husky Coatings – Bakersfield’s trusted commercial epoxy flooring contractor for industrial, commercial, and specialty projects.